Empowering DTCO Innovation with AI and Machine Learning(第1版)

活動訊息

內容簡介

Core Insight:

Cross-Domain Data Collaboration: Unlocking Chip Potential

Eliminating the "efficiency gap" caused by knowledge silos is the starting point for industry potential. Data doesn't lie; Data Science provides the solution: Through innovation and cross-domain restructuring, we visualize results to become the critical accelerator for boosting efficiency.

GenAI Reshaping the Future of Semiconductors

Facing the immense challenge of the slowing pace of Moore's Law, the semiconductor industry urgently requires new breakthroughs. This book is specifically designed to solve the "Efficiency Black Hole" that consumes tens of billions of dollars annually in the industry.

The Empowering DTCO Innovation with AI and Machine Learning offers readers a practical DTCO.ML Framework, demonstrating how to leverage Machine Learning (ML) and Generative AI (GenAI) technologies to inject new acceleration into chip manufacturing processes. Learn to master process variability and optimize chip energy efficiency, eliminating the time-consuming and costly physical tape-out trial-and-error cycle.

You Will Master: How to use data to transform Yield improvement from relying on lengthy trial-and-error into a predictable, controllable process with Accelerated ROI; achieving significant Energy Efficiency (EE) leaps in every product iteration; and gaining a Time-to-Market (TTM) competitive advantage of several months for your team.

Whether you are a chip design engineer, process R&D expert, or a manager seeking industry "re-acceleration" strategies, this book provides a validated AI-enabled strategy and execution blueprint. The future of DTCO starts here.

Cross-Domain Data Collaboration: Unlocking Chip Potential

Eliminating the "efficiency gap" caused by knowledge silos is the starting point for industry potential. Data doesn't lie; Data Science provides the solution: Through innovation and cross-domain restructuring, we visualize results to become the critical accelerator for boosting efficiency.

GenAI Reshaping the Future of Semiconductors

Facing the immense challenge of the slowing pace of Moore's Law, the semiconductor industry urgently requires new breakthroughs. This book is specifically designed to solve the "Efficiency Black Hole" that consumes tens of billions of dollars annually in the industry.

The Empowering DTCO Innovation with AI and Machine Learning offers readers a practical DTCO.ML Framework, demonstrating how to leverage Machine Learning (ML) and Generative AI (GenAI) technologies to inject new acceleration into chip manufacturing processes. Learn to master process variability and optimize chip energy efficiency, eliminating the time-consuming and costly physical tape-out trial-and-error cycle.

You Will Master: How to use data to transform Yield improvement from relying on lengthy trial-and-error into a predictable, controllable process with Accelerated ROI; achieving significant Energy Efficiency (EE) leaps in every product iteration; and gaining a Time-to-Market (TTM) competitive advantage of several months for your team.

Whether you are a chip design engineer, process R&D expert, or a manager seeking industry "re-acceleration" strategies, this book provides a validated AI-enabled strategy and execution blueprint. The future of DTCO starts here.

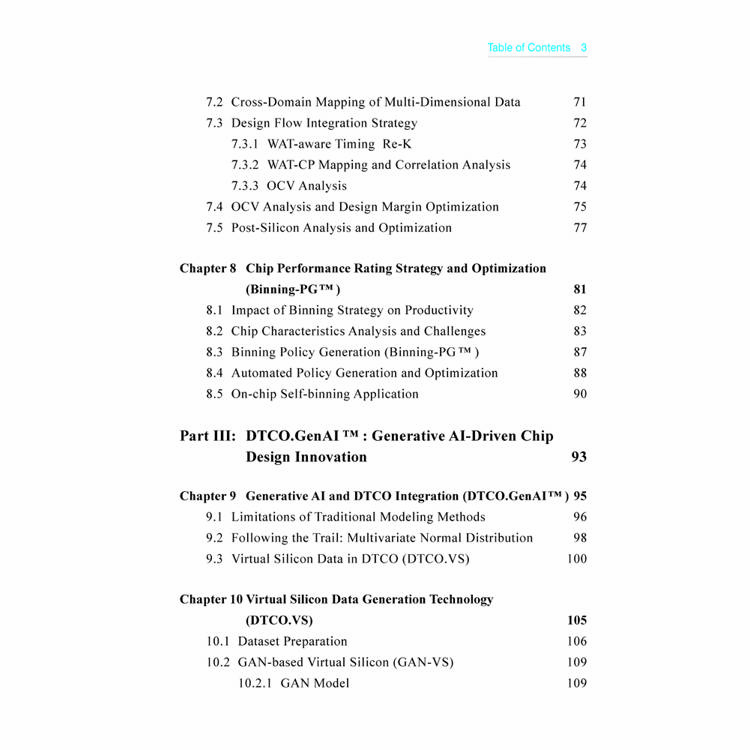

目錄

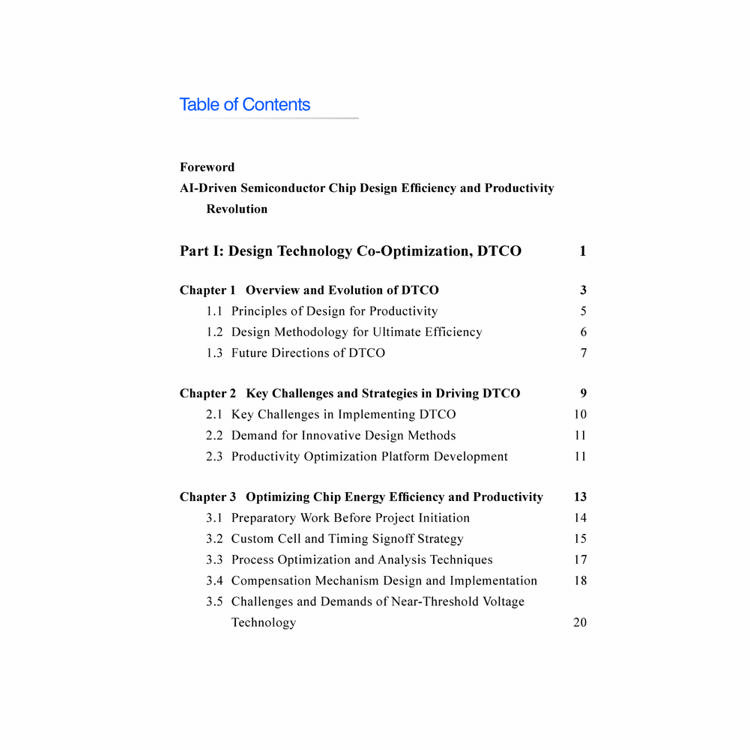

Table of Contents

Foreword

AI-Driven Semiconductor Chip Design Efficiency and Productivity Revolution

Part I: Design Technology Co-Optimization, DTCO

Chapter 1 Overview and Evolution of DTCO

1.1 Principles of Design for Productivity

1.2 Design Methodology for Ultimate Efficiency

1.3 Future Directions of DTCO

Chapter 2 Key Challenges and Strategies in Driving DTCO

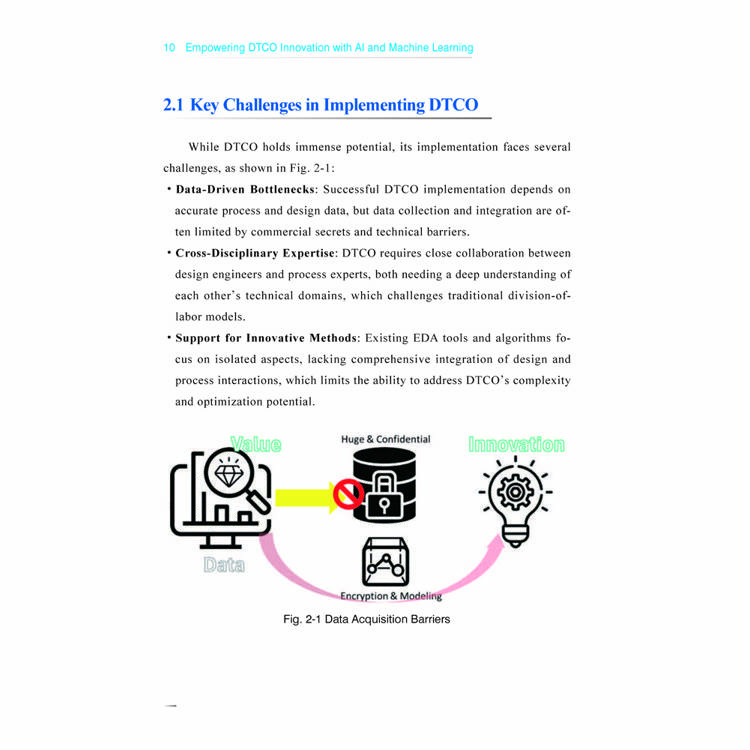

2.1 Key Challenges in Implementing DTCO

2.2 Demand for Innovative Design Methods

2.3 Productivity Optimization Platform Development

Chapter 3 Optimizing Chip Energy Efficiency and Productivity

3.1 Preparatory Work Before Project Initiation

3.2 Custom Cell and Timing Signoff Strategy

3.3 Process Optimization and Analysis Techniques

3.4 Compensation Mechanism Design and Implementation

3.5 Challenges and Demands of Near-Threshold Voltage Technology

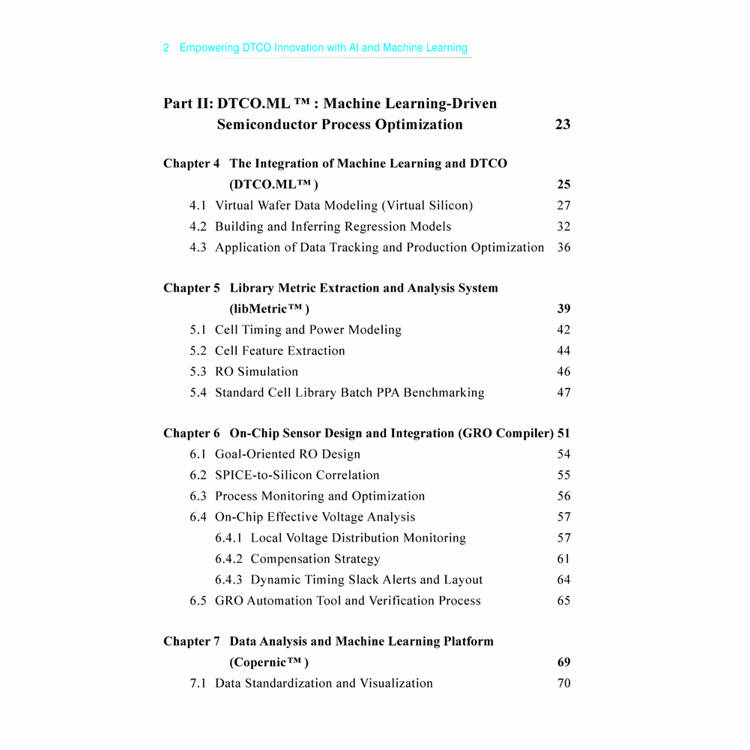

Part II: DTCO.ML ™ : Machine Learning-Driven Semiconductor Process Optimization

Chapter 4 The Integration of Machine Learning and DTCO (DTCO.ML ™ )

4.1 Virtual Wafer Data Modeling (Virtual Silicon)

4.2 Building and Inferring Regression Models

4.3 Application of Data Tracking and Production Optimization

Chapter 5 Library Metric Extraction and Analysis System (libMetric ™ )

5.1 Cell Timing and Power Modeling

5.2 Cell Feature Extraction

5.3 RO Simulation

5.4 Standard Cell Library Batch PPA Benchmarking

Chapter 6 On-Chip Sensor Design and Integration (GRO Compiler)

6.1 Goal-Oriented RO Design

6.2 SPICE-to-Silicon Correlation

6.3 Process Monitoring and Optimization

6.4 On-Chip Effective Voltage Analysis

6.4.1 Local Voltage Distribution Monitoring

6.4.2 Compensation Strategy

6.4.3 Dynamic Timing Slack Alerts and Layout

6.5 GRO Automation Tool and Verification Process

Chapter 7 Data Analysis and Machine Learning Platform (Copernic ™ )

7.1 Data Standardization and Visualization

7.2 Cross-Domain Mapping of Multi-Dimensional Data

7.3 Design Flow Integration Strategy

7.3.1 WAT-aware Timing Re-K

7.3.2 WAT-CP Mapping and Correlation Analysis

7.3.3 OCV Analysis

7.4 OCV Analysis and Design Margin Optimization

7.5 Post-Silicon Analysis and Optimization

Chapter 8 Chip Performance Rating Strategy and Optimization (Binning-PG ™ )

8.1 Impact of Binning Strategy on Productivity

8.2 Chip Characteristics Analysis and Challenges

8.3 Binning Policy Generation (Binning-PG ™ )

8.4 Automated Policy Generation and Optimization

8.5 On-chip Self-binning Application

Part III: DTCO.GenAI ™ : Generative AI-Driven Chip Design Innovation

Chapter 9 Generative AI and DTCO Integration (DTCO.GenAI ™ )

9.1 Limitations of Traditional Modeling Methods

9.2 Following the Trail: Multivariate Normal Distribution

9.3 Virtual Silicon Data in DTCO (DTCO.VS)

Chapter 10 Virtual Silicon Data Generation Technology (DTCO.VS)

10.1 Dataset Preparation

10.2 GAN-based Virtual Silicon (GAN-VS)

10.2.1 GAN Model

10.2.2 GAN Model Performance Evaluation

10.3 Diffusion Model-based Virtual Silicon (DM-VS)

10.3.1 Denoising Diffusion Probabilistic Model (DDPM))

10.3.2 Diffusion Model Performance Evaluation

Chapter 11 Generative AI-Driven Chip Efficiency Optimization and Modeling

11.1 WAT Super Resolution (WAT-SR)

11.2 High-Efficiency SPICE-Silicon Bias Modeling (He-SSBM)

11.2.1 Design Principle of One-shot SPICE-Silicon N/P Correlation

11.2.2 Design and Signoff Strategy Optimization

11.3 High-Fidelity Generative Monte Approximation (HΣ- GMA)

11.3.1 Limitations of Traditional Monte Carlo Methods

11.3.2 Innovative Application of Generative Neural Networks

Chapter 12 Conclusion and Outlook

12.1 AI-Enhanced DTCO: Revolutionizing Chip Design and Process Optimization (DTCO.ML ™ )

12.2 Generative AI-Driven Optimization (DTCO.GenAI ™ )

12.3 EDA Innovation and Future Outlook

Appendix

Open Source Resource List

Reference List

Glossary of Terms

Foreword

AI-Driven Semiconductor Chip Design Efficiency and Productivity Revolution

Part I: Design Technology Co-Optimization, DTCO

Chapter 1 Overview and Evolution of DTCO

1.1 Principles of Design for Productivity

1.2 Design Methodology for Ultimate Efficiency

1.3 Future Directions of DTCO

Chapter 2 Key Challenges and Strategies in Driving DTCO

2.1 Key Challenges in Implementing DTCO

2.2 Demand for Innovative Design Methods

2.3 Productivity Optimization Platform Development

Chapter 3 Optimizing Chip Energy Efficiency and Productivity

3.1 Preparatory Work Before Project Initiation

3.2 Custom Cell and Timing Signoff Strategy

3.3 Process Optimization and Analysis Techniques

3.4 Compensation Mechanism Design and Implementation

3.5 Challenges and Demands of Near-Threshold Voltage Technology

Part II: DTCO.ML ™ : Machine Learning-Driven Semiconductor Process Optimization

Chapter 4 The Integration of Machine Learning and DTCO (DTCO.ML ™ )

4.1 Virtual Wafer Data Modeling (Virtual Silicon)

4.2 Building and Inferring Regression Models

4.3 Application of Data Tracking and Production Optimization

Chapter 5 Library Metric Extraction and Analysis System (libMetric ™ )

5.1 Cell Timing and Power Modeling

5.2 Cell Feature Extraction

5.3 RO Simulation

5.4 Standard Cell Library Batch PPA Benchmarking

Chapter 6 On-Chip Sensor Design and Integration (GRO Compiler)

6.1 Goal-Oriented RO Design

6.2 SPICE-to-Silicon Correlation

6.3 Process Monitoring and Optimization

6.4 On-Chip Effective Voltage Analysis

6.4.1 Local Voltage Distribution Monitoring

6.4.2 Compensation Strategy

6.4.3 Dynamic Timing Slack Alerts and Layout

6.5 GRO Automation Tool and Verification Process

Chapter 7 Data Analysis and Machine Learning Platform (Copernic ™ )

7.1 Data Standardization and Visualization

7.2 Cross-Domain Mapping of Multi-Dimensional Data

7.3 Design Flow Integration Strategy

7.3.1 WAT-aware Timing Re-K

7.3.2 WAT-CP Mapping and Correlation Analysis

7.3.3 OCV Analysis

7.4 OCV Analysis and Design Margin Optimization

7.5 Post-Silicon Analysis and Optimization

Chapter 8 Chip Performance Rating Strategy and Optimization (Binning-PG ™ )

8.1 Impact of Binning Strategy on Productivity

8.2 Chip Characteristics Analysis and Challenges

8.3 Binning Policy Generation (Binning-PG ™ )

8.4 Automated Policy Generation and Optimization

8.5 On-chip Self-binning Application

Part III: DTCO.GenAI ™ : Generative AI-Driven Chip Design Innovation

Chapter 9 Generative AI and DTCO Integration (DTCO.GenAI ™ )

9.1 Limitations of Traditional Modeling Methods

9.2 Following the Trail: Multivariate Normal Distribution

9.3 Virtual Silicon Data in DTCO (DTCO.VS)

Chapter 10 Virtual Silicon Data Generation Technology (DTCO.VS)

10.1 Dataset Preparation

10.2 GAN-based Virtual Silicon (GAN-VS)

10.2.1 GAN Model

10.2.2 GAN Model Performance Evaluation

10.3 Diffusion Model-based Virtual Silicon (DM-VS)

10.3.1 Denoising Diffusion Probabilistic Model (DDPM))

10.3.2 Diffusion Model Performance Evaluation

Chapter 11 Generative AI-Driven Chip Efficiency Optimization and Modeling

11.1 WAT Super Resolution (WAT-SR)

11.2 High-Efficiency SPICE-Silicon Bias Modeling (He-SSBM)

11.2.1 Design Principle of One-shot SPICE-Silicon N/P Correlation

11.2.2 Design and Signoff Strategy Optimization

11.3 High-Fidelity Generative Monte Approximation (HΣ- GMA)

11.3.1 Limitations of Traditional Monte Carlo Methods

11.3.2 Innovative Application of Generative Neural Networks

Chapter 12 Conclusion and Outlook

12.1 AI-Enhanced DTCO: Revolutionizing Chip Design and Process Optimization (DTCO.ML ™ )

12.2 Generative AI-Driven Optimization (DTCO.GenAI ™ )

12.3 EDA Innovation and Future Outlook

Appendix

Open Source Resource List

Reference List

Glossary of Terms

序/導讀

Preface

In the era of AI-driven innovation, the semiconductor industry is shifting from traditional yield optimization to comprehensive productivity enhancement. To stay competitive, chip design now focuses on enhancing performance, production capacity, and market competitiveness, beyond just yield and cost. This book explores how AI can optimize design margins, timing signoff, testing strategies, data analysis, process adjustments, binning strategies, and system-level compensation, driving a revolution in semiconductor design and productivity.

Book Positioning

This book approaches semiconductor design from a physical implementation perspective, focusing on the application of machine learning (ML) in Design-Technology Co-Optimization (DTCO). It covers traditional ML and cuttingedge generative AI (GenAI), exploring strategies to enhance chip performance and productivity.

Target Audience

Semiconductor Professionals: Chip design engineers, EDA developers, and researchers, offering practical examples and insights.

Cross-Disciplinary Researchers: Helping them understand DTCO and explore AI applications.

Book Structure

We introduce DTCO principles, discuss machine learning applications in optimization, and analyze how generative AI shapes the future of semiconductor design. The book also explores innovative EDA development, showing how new technologies improve design efficiency and performance.

In the era of AI-driven innovation, the semiconductor industry is shifting from traditional yield optimization to comprehensive productivity enhancement. To stay competitive, chip design now focuses on enhancing performance, production capacity, and market competitiveness, beyond just yield and cost. This book explores how AI can optimize design margins, timing signoff, testing strategies, data analysis, process adjustments, binning strategies, and system-level compensation, driving a revolution in semiconductor design and productivity.

Book Positioning

This book approaches semiconductor design from a physical implementation perspective, focusing on the application of machine learning (ML) in Design-Technology Co-Optimization (DTCO). It covers traditional ML and cuttingedge generative AI (GenAI), exploring strategies to enhance chip performance and productivity.

Target Audience

Semiconductor Professionals: Chip design engineers, EDA developers, and researchers, offering practical examples and insights.

Cross-Disciplinary Researchers: Helping them understand DTCO and explore AI applications.

Book Structure

We introduce DTCO principles, discuss machine learning applications in optimization, and analyze how generative AI shapes the future of semiconductor design. The book also explores innovative EDA development, showing how new technologies improve design efficiency and performance.

配送方式

-

台灣

- 國內宅配:本島、離島

-

到店取貨:

不限金額免運費

-

海外

- 國際快遞:全球

-

港澳店取:

訂購/退換貨須知

退換貨須知:

**提醒您,鑑賞期不等於試用期,退回商品須為全新狀態**

-

依據「消費者保護法」第19條及行政院消費者保護處公告之「通訊交易解除權合理例外情事適用準則」,以下商品購買後,除商品本身有瑕疵外,將不提供7天的猶豫期:

- 易於腐敗、保存期限較短或解約時即將逾期。(如:生鮮食品)

- 依消費者要求所為之客製化給付。(客製化商品)

- 報紙、期刊或雜誌。(含MOOK、外文雜誌)

- 經消費者拆封之影音商品或電腦軟體。

- 非以有形媒介提供之數位內容或一經提供即為完成之線上服務,經消費者事先同意始提供。(如:電子書、電子雜誌、下載版軟體、虛擬商品…等)

- 已拆封之個人衛生用品。(如:內衣褲、刮鬍刀、除毛刀…等)

- 若非上列種類商品,均享有到貨7天的猶豫期(含例假日)。

- 辦理退換貨時,商品(組合商品恕無法接受單獨退貨)必須是您收到商品時的原始狀態(包含商品本體、配件、贈品、保證書、所有附隨資料文件及原廠內外包裝…等),請勿直接使用原廠包裝寄送,或於原廠包裝上黏貼紙張或書寫文字。

- 退回商品若無法回復原狀,將請您負擔回復原狀所需費用,嚴重時將影響您的退貨權益。

商品評價